Table of Contents

ToggleIntroduction

In the realm of precision optics, the quality and performance of optical lenses are paramount. Whether it’s for red dot sights, prism scopes, or riflescopes, the meticulous process of manufacturing and inspecting these lenses ensures that they meet the highest standards of clarity, durability, and accuracy. This article delves into the detailed steps involved in the processing technology, manufacturing processes, and quality inspection of these critical components, highlighting the importance of each phase from raw material selection to final inspection.

Raw Materials

The selection of raw materials is crucial in the processing of optical lenses for red dot sights. High-quality optical glass materials not only ensure the lens’s light transmission and durability but also directly affect the finished product’s optical performance. Common raw materials include high-purity optical glass, which must undergo strict testing and screening before processing to ensure its chemical composition and physical properties meet the standards. High-quality raw materials are the first step in ensuring lens quality and are a fundamental aspect of the entire manufacturing process.

Rough Grinding

Rough grinding (lapping) involves using advanced machinery to perform single-piece grinding, achieving a certain radius of curvature and surface roughness on the lens. After rough grinding, the lens’s refractive power is shaped, but the surface remains rough and semi-transparent.

Fine Grinding

Fine grinding is a critical step in enhancing the performance of red dot sight lenses. Using diamond pellets for grinding, this process improves the surface roughness of the lens after rough grinding without altering its radius of curvature. The lens comes into contact with molds that have polishing pads or grinding discs, and the mold’s radius matches the curvature of the lens. During the operation, which lasts several minutes, the lens should achieve the desired thickness and curvature, though the surface remains somewhat rough.

Polishing

Polishing, done with the same equipment as fine grinding but using different abrasives, involves the use of polyurethane and cerium oxide polishing pads. The aim is to eliminate surface machining marks from fine grinding, achieving smoothness, transparency, and correct refractive power, providing the lens with the required clarity. Professional molds are used in both polishing and fine grinding, with mold surfaces matching the processed lens’s curvature.

Edge Grinding

Edge grinding involves grinding the lens’s outer diameter to the specified size and refining the edges. This step not only removes rough edges but also ensures the lens attains the desired shape and dimensions. High-precision grinding equipment and meticulous process control make the lens edges smooth and compliant with design requirements.

Ultrasonic Cleaning

Ultrasonic cleaning uses cavitation effects produced by ultrasonic vibrations to deeply clean the lens, effectively removing oil, dust, and other particles from the lens surface and micropores. This method improves cleaning efficiency and avoids physical damage that traditional cleaning methods might cause. Post-cleaning, the lens must undergo strict drying to ensure its surface is completely free of water spots and contaminants.

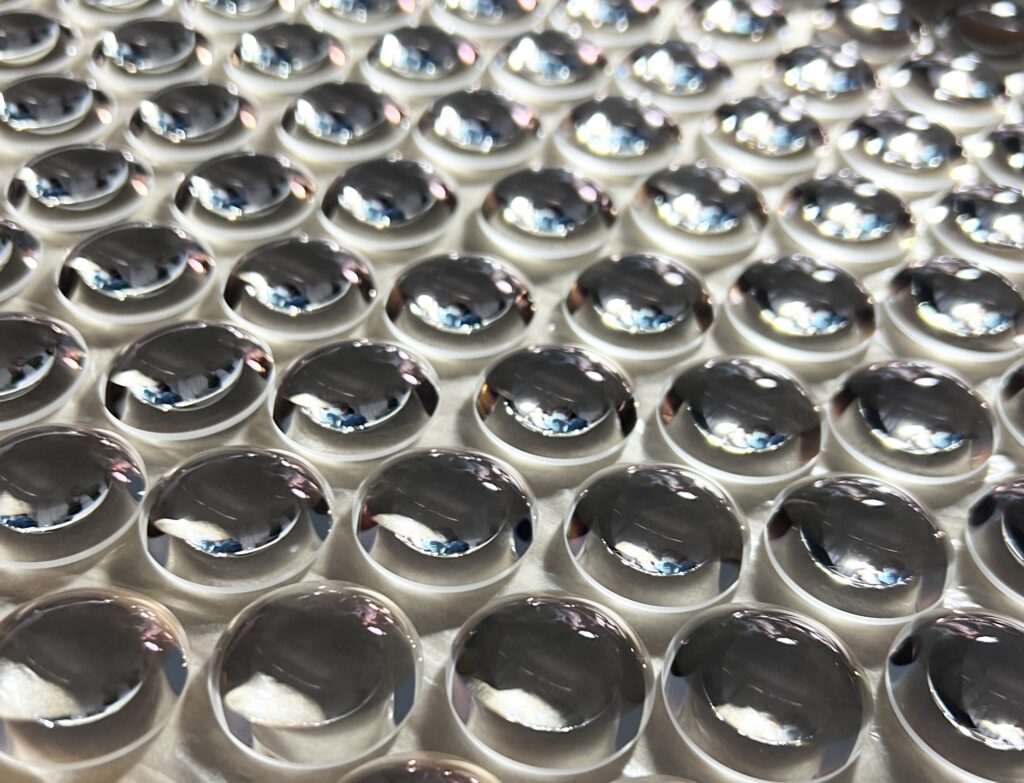

Cleanliness Inspection Before Mounting

Before placing the lenses into the coating tray, a thorough cleanliness inspection is essential. This step ensures that each lens is free of contaminants or particles before the coating phase, preventing any adverse effects on the coating quality.

Mounting Molds (Coating Trays)

Mounting molds involve placing cleaned lenses one by one into the coating tray, requiring meticulousness and precision from the operators. Each lens must be correctly fixed in the tray without touching or rubbing against others. The design of the coating trays considers the vacuum environment and uniformity of material evaporation during coating, with high technical requirements for the tray’s material and structure. The quality of mounting directly affects coating results and production efficiency.

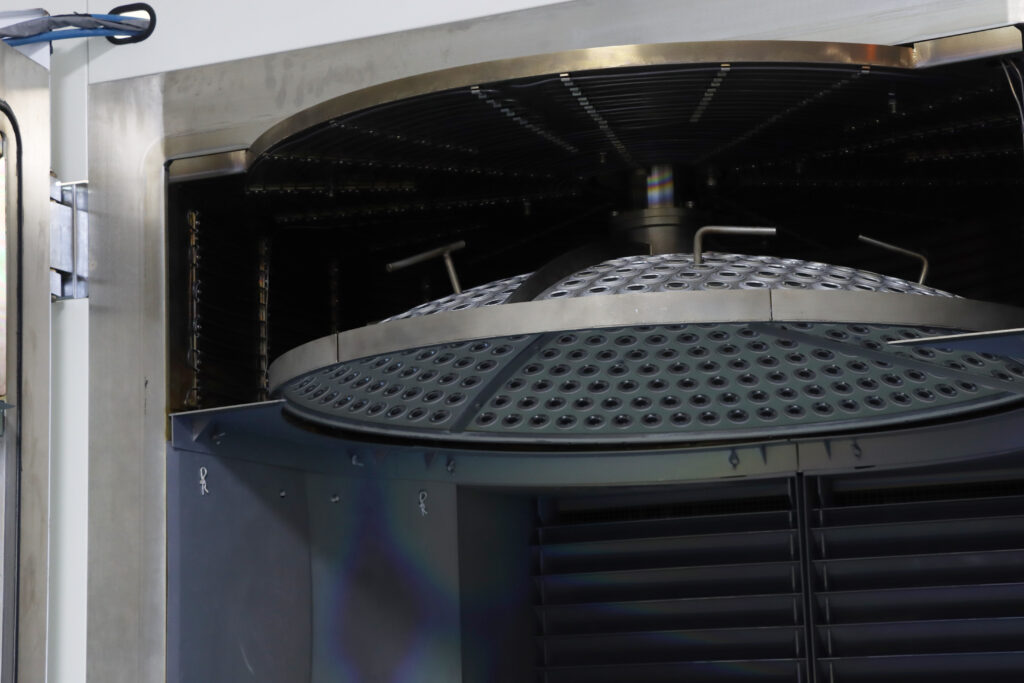

Coating

Coating is a critical stage in the manufacture of red dot sight lenses. Using automated coating machines, material is uniformly evaporated onto the lens surface in a vacuum environment to ensure uniformity and stability of the coating layer. The coating machine employs electron gun technology to vaporize the material at high temperatures, uniformly depositing it on the lens to form thin films with specific optical properties. The coating color and layers are chosen based on customer requirements.

Cementing

Cementing involves bonding two lenses with opposing R-values and identical outer diameter materials using adhesive, forming multi-layer lenses with complex optical properties. The adhesive’s optical performance must match the lens materials, and the bonding process requires strict control of environmental temperature and humidity to avoid bubbles and uneven adhesive layers. Cemented lenses undergo curing to ensure structural stability and optical performance. The quality of cementing is crucial to multi-layer lens performance, requiring meticulous attention to every detail during the process.

Quality Inspection

Quality inspection is the final step to ensure the quality of red dot sight lenses. This process includes comprehensive checks of the lens’s appearance, dimensions, and optical performance, ensuring each lens meets design requirements and quality standards. Qualified lenses proceed to the packaging stage, while defective products are reworked or discarded. Rigorous quality inspection procedures are vital to ensuring lens quality and customer satisfaction.

Through these detailed processes, the manufacture of optical lenses for red dot sights, prism scopes, and riflescopes ensures high standards of performance and quality, meeting the exacting demands of modern optical applications.